Tyre racks have been gaining a growing number of attention for tyre shops, dealers and wholesalers over the last decade.

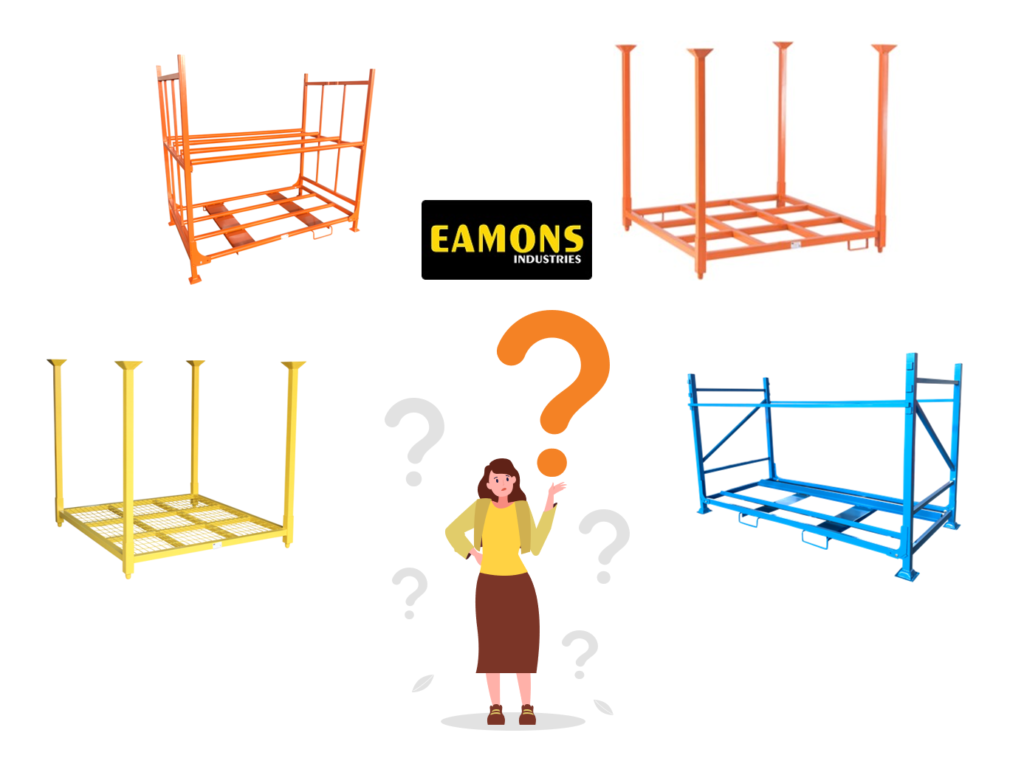

Compared with the fixed and rigid space layout of pallet racking for tyre storage, customers are getting more and more interested in mobile tyre racks. Because they are stackable and foldable in structure, your floor space is always roomy and flexible to use.

In this post, we’ll list 3 tips to help you find the right tyre rack in less than 5 minutes.

- Types of tyres to be stored

- Position of tyres to be stored

- Average freight costs

So let’s dive in.

Types of tyres

This is the starting point to select a tyre rack. And the self-help question is quite simple:

Do you need tyre racks for big tyres or small tyres?

—Eamons Tyre Racks

This is the most basic question before you purchase tyre racks. It’s like before you climb the ladder, make sure that you set it up against the right wall. Hence, you answer to this question will point you to the right direction.

Big tyres refer to truck and bus tyres.

Passenger car tyres, SUV tyres, light truck tyres, and industrial tyres are grouped under “small tyres”.

If you need big tyres like 10.00R20, 11R22.5, 11R24.5, 295/85R22.5, 315/80R22.5 or even 385/65R22.5, you can check out all our tyre racks for truck tyre storage.

If you are looking for tyre racks for tyres like 195/65R15, 205/55R16, LT235/85R16, you can take a look at all our tyre racks for car tyre storage.

If it’s still beyond your range of knowledge, please read this basic knowledge of tires. Or you can just contact for your concerns.

Tyres’ position on tyre racks

There are 3 ways to store tyres: on treads, on sidewalls or laced.

For tyres stored on treads, they are standing upright.

When on sidewalls, tyres are flat and can be barrel stacked.

Being laced, tyres nest into each other with an angle. And this way of storage applies only to car tyres. It’s impossible to get truck tyres interlaced into each other, because they’re way too heavy.

The list below reveals how the tyre rack handles your tyre inventory.

Truck and Bus Tyre Racks

Car Tyre Racks (On Sidewall)

Car Tyre Racks (On Treads and Laced)

Average freight costs per tyre rack

Since the outburst of COVID-19, the sea freight rates worldwide have been rocketing. Consequently, the average rate goes north of USD10,000/40HC for some American and European ports.

This headache is out of our control, but it doesn’t stop us from getting proactive. Instead, it drives us to think which tyre racks can offset the increase in freight costs for our customers?

The math is simple. With freight rates fixed, the more we can load into a container, the cheaper the average cost goes.

For truck and bus tyres, if you can accept barrel stacking, then TBR2000-A is undoubtedly the most economic option.

We can load 240 racks in a 40ft container. Each rack can handle 12 tyres of 11R22.5, so a full container of tyre racks can handle 2,880 tyres easily.

For passenger car tyres, PCR1000-A or PCR1000-B is always the best option.

We can load 280 racks in a 40ft container. Each rack can handle 30 tyres of 205/55R16, thus a full container of tyre racks can handle 8,400 tyres easily.

Conclusion

If our models on offer don’t suit your warehousing requirement, please send an email with your question. We have a whole engineering team to work out the solution.

Contact us today to get a price quote.